🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

At Infinity Market Research, we dont just deliver data — we deliver clarity, confidence, and competitive edge.

In a world driven by insights, we help businesses unlock the infinite potential of informed decisions.

Here why global brands, startups, and decision-makers choose us:

Industry-Centric Expertise

With deep domain knowledge across sectors — from healthcare and technology to manufacturing and consumer goods — our team delivers insights that matter.

Custom Research, Not Cookie-Cutter Reports

Every business is unique, and so are its challenges. Thats why we tailor our research to your specific goals, offering solutions that are actionable, relevant, and reliable.

Data You Can Trust

Our research methodology is rigorous, transparent, and validated at every step. We believe in delivering not just numbers, but numbers that drive real impact.

Client-Centric Approach

Your success is our priority. From first contact to final delivery, our team is responsive, collaborative, and committed to your goals — because you re more than a client; you re a partner.

Recent Reports

Obesity Management Market

GLP-1 Receptor Agonist Market

Vertical Injection Molding Machine Market

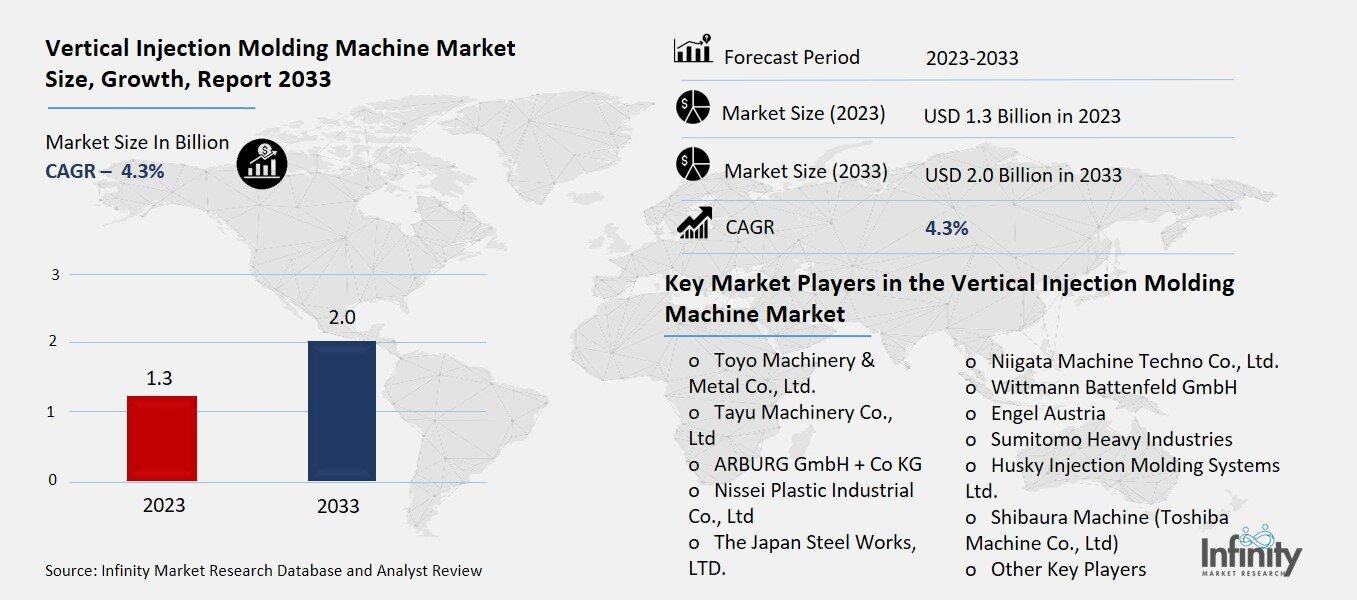

Global Vertical Injection Molding Machine Market (Machine Type, Hydraulic, Hybrid, and All-Electric; By Material, Rubber, Plastic, Ceramic, Metal, and Other Materials; By Application, Healthcare, Automotive, Packaging, Electrical & Electronics, Consumer Goods, and Other Applications; By Region and Companies), 2024-2033

Oct 2024

Industrial Automation and Equipment

Pages: 138

ID: IMR1253

Vertical Injection Molding Machine Market Overview

Global Vertical Injection Molding Machine Market acquired the significant revenue of 1.3 Billion in 2023 and expected to be worth around USD 2.0 Billion by 2033 with the CAGR of 4.3% during the forecast period of 2024 to 2033. The market for vertical injection molding machine is expected to increase substantially, due to the ever-growing demand for precisely engineered plastic components in areas such as automotive components, consumer goods and medical devices.

Vertical injection molding machines offer superior space-saving benefit and increased efficiency meaning reductions in material usage and high precision in forming complex parts. Besides this, as automation becomes more and more integrated and prevalent, the increased functional flexibility associated with multi-component and insert molding capabilities are making these machines even more appealing. Likewise, green manufacturing principles are fast becoming mainstream as manufacturers seek out machines that are more energy-efficient and minimize production wastage.

Drivers for the Vertical Injection Molding Machine Market

Increasing Demand for Lightweight Components

The automotive and aerospace industries are increasingly prioritizing lightweight components to improve fuel efficiency, reduce emissions, and enhance overall performance. Vertical injection molding machines play a crucial role in this shift by enabling the production of complex, lightweight plastic parts that meet stringent industry standards. These machines are designed to handle a variety of advanced thermoplastics and composites that provide the necessary strength and durability while significantly reducing weight compared to traditional materials.

The precise control offered by vertical injection molding allows manufacturers to produce intricate designs and features that can be integrated into various applications, from interior trim to structural components. Additionally, as automakers and aerospace manufacturers strive to meet regulatory requirements and consumer demands for sustainability, the ability to produce lightweight plastic parts efficiently aligns perfectly with their goals.

Restraints for the Vertical Injection Molding Machine Market

Limited Applicability for Certain Designs

While vertical injection molding machines excel in producing specific applications, such as small, complex parts or components requiring insert molding, they face limitations that can restrict their market appeal across various sectors. Their design inherently favors applications where gravity can aid in the molding process, making them less suitable for larger parts or products that require extensive cooling time, as these typically benefit from the characteristics of horizontal machines. Additionally, vertical machines may struggle with high-volume production of larger items, as they usually have a lower clamping force compared to their horizontal counterparts.

Opportunity in the Vertical Injection Molding Machine Market

Rapid Industrialization and Increasing Manufacturing Activities

Rapid industrialization and increasing manufacturing activities in emerging economies are creating significant growth opportunities for vertical injection molding machines. As countries in regions such as Asia-Pacific, Latin America, and parts of Africa strive to enhance their manufacturing capabilities, there is a burgeoning demand for efficient and cost-effective production solutions. Vertical injection molding machines, known for their space-saving designs and ability to produce complex, high-quality plastic components, align well with the needs of these expanding markets. The growing automotive, consumer goods, and packaging sectors in emerging economies are particularly driving this demand, as manufacturers seek to adopt advanced technologies that facilitate faster production cycles while maintaining quality.

Trends for the Vertical Injection Molding Machine Market

Increased Use of Advanced Materials

The growing trend toward using engineered plastics and composites is significantly impacting the vertical injection molding market, as these materials offer enhanced properties such as strength, durability, and lightweight characteristics. Engineered plastics, including nylon, polycarbonate, and acrylonitrile butadiene styrene (ABS), are increasingly favored across various industries for their ability to withstand harsh conditions, provide design flexibility, and improve overall product performance. Vertical injection molding technology is particularly well-suited for processing these advanced materials due to its precise control over injection speed and pressure, which is essential for achieving optimal material flow and filling complex molds. Additionally, the capability of vertical machines to incorporate multiple components or inserts within a single molding cycle allows for the efficient production of hybrid parts that combine engineered plastics with other materials, further enhancing functionality and design options.

Segments Covered in the Report

By Machine Type

o Hydraulic

o Hybrid

o All-Electric

By Material

o Rubber

o Plastic

o Ceramic

o Metal

o Other Materials

By Application

o Healthcare

o Automotive

o Packaging

o Electrical & Electronics

o Consumer Goods

o Other Applications

Segment Analysis

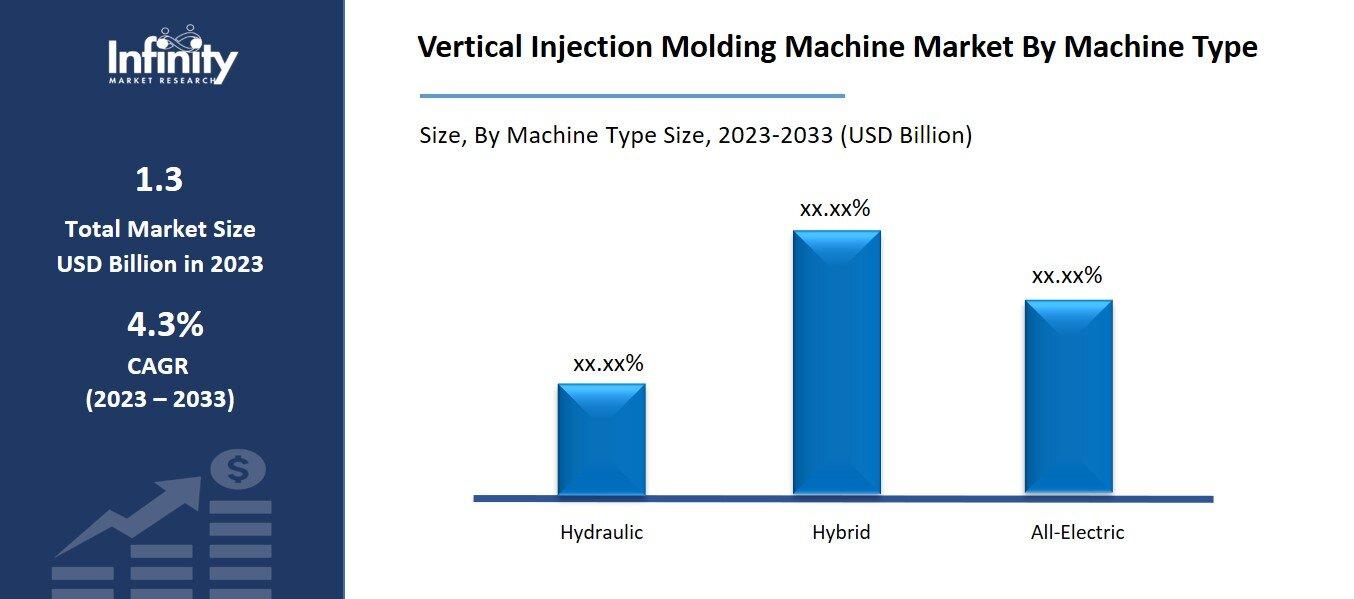

By Machine Type Analysis

On the basis of machine type, the market is divided into hydraulic, hybrid, and all-electric. Among these, hydraulic segment acquired the significant share around 37.4% in the market owing to its robust performance, reliability, and cost-effectiveness in handling a wide range of applications. Hydraulic machines are known for their strong clamping force, which is essential for producing larger and more complex components with high precision. This capability makes them particularly appealing in industries such as automotive and packaging, where durability and dimensional accuracy are critical.

Furthermore, hydraulic machines often have lower initial investment costs compared to all-electric alternatives, making them an attractive option for small and medium-sized enterprises looking to optimize production without incurring substantial financial burdens.

By Material Analysis

On the basis of material, the market is divided into rubber, plastic, ceramic, metal, and other materials. Among these, rubber held the prominent share of the market due to its extensive application across various industries, particularly in the production of automotive components, seals, gaskets, and flexible parts. The versatility and durability of rubber make it an ideal material for products that require excellent elasticity, resilience, and weather resistance.

Additionally, the growing demand for rubber components in the automotive sector, driven by the increasing need for lightweight and fuel-efficient vehicles, has further solidified its market position. Rubber's ability to be molded into intricate shapes and forms using vertical injection molding technology allows manufacturers to create complex designs that meet specific performance criteria.

By Application Analysis

On the basis of application, the market is divided into healthcare, automotive, packaging, electrical & electronics, consumer goods, and other applications. Among these, automotive held the significant share of the market due to the increasing demand for lightweight, durable, and high-performance components that meet stringent regulatory standards. The automotive industry relies heavily on vertical injection molding technology to produce various plastic parts, including interior and exterior components, dashboards, bumpers, and under-the-hood applications, which require precise engineering and high-quality finishes.

Regional Analysis

Asia Pacific Dominated the Market with the Highest Revenue Share

Asia Pacific held the most of the share of 32.1% of the market. The growing demand for lightweight and durable plastic components in the automotive and electronics industries has further propelled the market for vertical injection molding machines in this region. Countries like China, being one of the largest automotive producers globally, are increasingly adopting advanced manufacturing technologies to enhance production efficiency and meet the rising consumer demand.

Additionally, the presence of numerous manufacturers and suppliers in the Asia Pacific region has fostered a competitive landscape, leading to continuous innovations and cost reductions in machine production. Government initiatives promoting local manufacturing, coupled with investments in infrastructure and technology, are also contributing to the growth of the vertical injection molding machine market in the region.

Competitive Analysis

The competitive landscape of the vertical injection molding machine market is characterized by a diverse array of global and regional players striving to capture market share through innovation, technological advancements, and strategic partnerships. Key players, including established manufacturers such as Engel, Arburg, and Haitian International, dominate the market with their extensive product portfolios and strong brand reputations. These companies are focusing on research and development to enhance machine efficiency, precision, and sustainability, aiming to meet the evolving demands of various industries.

Recent Developments

In December 2022, JSW introduced the JLM3000-MGIIeL, a magnesium injection molding machine featuring a mold clamping force of 3,000 tons (29,400 kN), making it the largest in the world. This new model follows the 1,300-ton mold clamping force of the JLM-MGIIe series.

Key Market Players in the Vertical Injection Molding Machine Market

o Toyo Machinery & Metal Co., Ltd.

o Tayu Machinery Co., Ltd

o ARBURG GmbH + Co KG

o Nissei Plastic Industrial Co., Ltd

o The Japan Steel Works, LTD.

o Shibaura Machine (Toshiba Machine Co., Ltd)

o Niigata Machine Techno Co., Ltd.

o Wittmann Battenfeld GmbH

o Engel Austria

o Sumitomo Heavy Industries

o Husky Injection Molding Systems Ltd.

o Other Key Players

|

Report Features |

Description |

|

Market Size 2023 |

USD 1.3 Billion |

|

Market Size 2033 |

USD 2.0 Billion |

|

Compound Annual Growth Rate (CAGR) |

4.3% (2023-2033) |

|

Base Year |

2023 |

|

Market Forecast Period |

2024-2033 |

|

Historical Data |

2019-2022 |

|

Market Forecast Units |

Value (USD Billion) |

|

Report Coverage |

Revenue Forecast, Market Competitive Landscape, Growth Factors, and Trends |

|

Segments Covered |

By Machine Type, Material, Application, and Region |

|

Geographies Covered |

North America, Europe, Asia Pacific, and the Rest of the World |

|

Countries Covered |

The U.S., Canada, Germany, France, U.K, Italy, Spain, China, Japan, India, Australia, South Korea, and Brazil |

|

Key Companies Profiled |

Toyo Machinery & Metal Co., Ltd., Tayu Machinery Co., Ltd, ARBURG GmbH + Co KG, Nissei Plastic Industrial Co., Ltd, The Japan Steel Works, LTD., Shibaura Machine (Toshiba Machine Co., Ltd), Niigata Machine Techno Co., Ltd., Wittmann Battenfeld GmbH, Engel Austria, Sumitomo Heavy Industries, Husky Injection Molding Systems Ltd., and Other Key Players. |

|

Key Market Opportunities |

Rapid Industrialization and Increasing Manufacturing Activities |

|

Key Market Dynamics |

Increasing Demand for Lightweight Components |

📘 Frequently Asked Questions

1. How much is the Vertical Injection Molding Machine Market in 2023?

Answer: The Vertical Injection Molding Machine Market size was valued at USD 1.3 Billion in 2023.

2. What would be the forecast period in the Vertical Injection Molding Machine Market?

Answer: The forecast period in the Vertical Injection Molding Machine Market report is 2024-2033.

3. Who are the key players in the Vertical Injection Molding Machine Market?

Answer: Toyo Machinery & Metal Co., Ltd., Tayu Machinery Co., Ltd, ARBURG GmbH + Co KG, Nissei Plastic Industrial Co., Ltd, The Japan Steel Works, LTD., Shibaura Machine (Toshiba Machine Co., Ltd), Niigata Machine Techno Co., Ltd., Wittmann Battenfeld GmbH, Engel Austria, Sumitomo Heavy Industries, Husky Injection Molding Systems Ltd., and Other Key Players.

4. What is the growth rate of the Vertical Injection Molding Machine Market?

Answer: Vertical Injection Molding Machine Market is growing at a CAGR of 4.3% during the forecast period, from 2023 to 2033.

🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

- Accurate & Verified Data:Our insights are trusted by global brands and Fortune 500 companies.

- Complete Transparency:No hidden fees, locked content, or misleading claims — ever.

- 24/7 Analyst Support:Our expert team is always available to help you make smarter decisions.

- Instant Savings:Enjoy a flat $1000 OFF on every report.

- Fast & Reliable Delivery:Get your report delivered within 5 working days, guaranteed.

- Tailored Insights:Customized research that fits your industry and specific goals.