🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

At Infinity Market Research, we dont just deliver data — we deliver clarity, confidence, and competitive edge.

In a world driven by insights, we help businesses unlock the infinite potential of informed decisions.

Here why global brands, startups, and decision-makers choose us:

Industry-Centric Expertise

With deep domain knowledge across sectors — from healthcare and technology to manufacturing and consumer goods — our team delivers insights that matter.

Custom Research, Not Cookie-Cutter Reports

Every business is unique, and so are its challenges. Thats why we tailor our research to your specific goals, offering solutions that are actionable, relevant, and reliable.

Data You Can Trust

Our research methodology is rigorous, transparent, and validated at every step. We believe in delivering not just numbers, but numbers that drive real impact.

Client-Centric Approach

Your success is our priority. From first contact to final delivery, our team is responsive, collaborative, and committed to your goals — because you re more than a client; you re a partner.

Recent Reports

Obesity Management Market

GLP-1 Receptor Agonist Market

Vibration Damping Material Market

Vibration Damping Material Market Global Industry Analysis and Forecast (2024-2032) By Material Type(Rubber, Polyurethane, Cork, Foam, Composites, Others), By End-Use Industry(Automotive, Aerospace & Defense, Industrial Equipment, Consumer Electronics, Construction, Marine, Others), By Application(Noise Control, Vibration Control, Shock Absorption) and Region

Feb 2025

Chemicals and Materials

Pages: 138

ID: IMR1671

Vibration Damping Material Market Synopsis

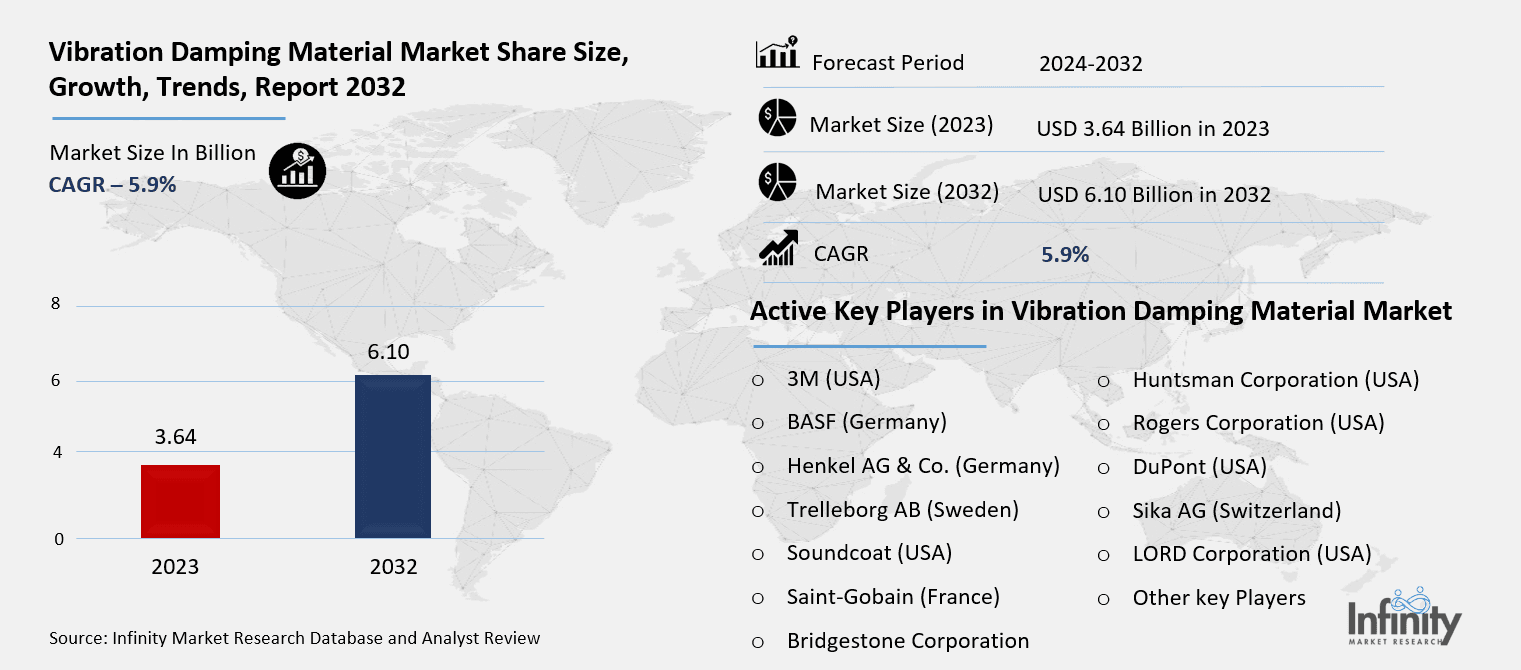

Vibration Damping Material Market Size Was Valued at USD 3.64 Billion in 2023, and is Projected to Reach USD 6.10 Billion by 2032, Growing at a CAGR of 5.9% From 2024-2032.

The Vibration Damping Material Market will mean the trade which is engaged in manufacturing or supplying the products that are especially produced to lessen the degrees of vibration as well as the noise produced by mechanical equipment, systems or structures. These materials are employed in automobile, aerospace, construction and manufacturing sectors for enhancing comfort, efficiency, and durability by reducing, isolating or damped vibrations and sound energy. Examples of Other Vibration Damping Products that are used are polymers, elastomers, composites & various other specialty products as per specific application requirements, have ability to reduce vibration & hence protect equipments and also have feature to minimize noise.

The most apparent reason for the current growth of the Vibration Damping Material Market is noise and vibration control in a wide range of industrial field. As production technology progresses further, these materials are increasingly permeating industries such as automotive and aerospace, construction, and home electronics. Random vibrations from these sources affect the efficiency of operations, reliability of equipment, and morality of structures affecting occupants. This has dictated the market demand as products such as vibration damping materials can boost the efficiency of products, increase safety, and in the long-run increase the lifespan of machinery.

Other factors include the technological factor which has seen polymers and composite material developed to enhance the market. Following the emerging trends in sustainable developments, the use of natural products such as natural rubber, cork and recycled commodity composites continues to rise. In addition, increased awareness of environmental consequences and noise emissions is creating demand for vibration damping systems in industries. As well as serving the purpose of vibration attenuation, these materials are aimed at saving energy through low power transmission through mechanical oscillations.

In the automotive field, the vibration damping material has its usage in enhancing ride acoustic and mechanics comfort, reducing pertinent sound levels as well as increasing a vehicle’s life span. In aerospace application they are applied to help minimize effects of the engine and airframe vibration thus both structurally and in passenger comfort. Also, electronics industry and construction require damping solutions necessary to protect the delicate machineries and avoid interrupting the peaceful activities in homes and businesses. As these industries advance, so does the need for some vibration damping material specific to each of them.

Technological advancements have continued to embrace miniaturization of devices in electronics and Mobile technologies; this calls for high performance, compact, lightweight and efficient damping materials. Further, increasing global EVs sales, along with key renewable energy products such as wind turbines and solar power systems, fuel the market’s expansion. Additional opportunities in the element’s demand in forthcoming years can be attributed to the growth of the market in the emerging economies and the escalating concern towards noise and vibration control.

Vibration Damping Material Market Outlook, 2023 and 2032: Future Outlook

Vibration Damping Material Market Trend Analysis

Trend: Use of Eco-Friendly and Sustainable Materials

Owing to the prevailing concerns regarding the rate of destruction of the environment there has been the use of environmentally friendly and sustainable materials in the vibration damping systems. To address the environmental problem of resource and disposal, manufacturers have begun to use renewable resources and recyclable material. Natural rubber, cork and biological based composite materials are emerging as ideal materials because of their lowered carbon emissions and biodegradable natures. These materials are either as effective, or in some cases, more effective than current synthetic materials, thus making them the best choice for the environmentally conscious client and companies. Given the increased interest in sustainable products, it can be anticipated that in the future, the growth of the Vibration Damping Material Market will be characterised by greater use of environmentally friendly products.

Also, the growth of GREEN technologies and thus the increased concentration on the adherence to the legal requirements for environmental protection pushes producers into offering and into researching for better solutions. The implementation of the regulations does not only compel organisations to use biodegradable or recyclable products but this is further aided by the fact that there is a growing appropriateness to sustainable products. It is likely to help to increase the pace of the search for new materials and their applications, especially in such areas as auto industry, construction, and consumer electronics, where the reduction of the negative impact on the environment is becoming critical.

Opportunity: Growing Demand for Electric Vehicles (EVs)

The need for electric cars which has risen due to global climate change is a great opportunity the Vibration Damping Material Market. Since the development of the automotive industry to electric vehicles, the comfort, performance and efficiency of EVs are enhanced. With help of Vibration damping material at EVs, road noise, engine vibration as well as noises emerging transmission system can be minimized to deliver a refined ride. As electric powertrains produce less vibrations than traditional Internal Combustion Engines, there is growing demand for damping systems specific to new vehicles.

Secondly, as the adoption of electoral vehicles is on the rise among people, the automotive companies are focusing on research to establish new materials that can increase battery durability, minimize the weight, and increase energy density. Therefore, the damping materials that are used are gradually being tuned to meet the needs of the EVs opening up a new market opportunity. The increasing customer demands for low noise and comfortable ride as well as continuous increase in the noise standards set by supreme courts across the globe also in urban areas have increased more potentiality for the manufacturers involved in manufacturing of new materials for vibration damping to fulfil its potential in the automotive market.

Driver: Technological Advancements in Material Science

Innovations in the field of material science remain one of the biggest forces behind Industry growth in the Vibration Damping Material Market. Several techniques and approaches are still being conducted by researchers to increase the effectiveness of damping material to improve the damping performance and durability, weight and other characteristics. Recent advancement in polymer science, composite construction, and nanotechnology opened up new avenues in the development of advanced damping materials suitable for high temperature and mechanical straining rates and corrosive environment. They are gaining popularity in automotive, aerospace, and construction industries, where reliability and durability of the material sets the key performance parameters.

This development coupled with improvement in constructions such as those that employ the piezoelectric smart material for active control of vibrations is expected to fuel market expansion. Such materials can sense and evaluate mechanical shifts which in turn provide narrower ranges of vibration isolation. These solutions are reshaping industries’ approach to vibration control by offering improved and more sustainable outcomes. Ongoing advancement in material science is likely to have greater impact on growth for the market and increasing customer standards hence the need to develop more advanced damping solutions.

Restraints: High Cost of Advanced Materials

The Vibration Damping Material Market faces significant challenges such as high cost in relation to advanced damping materials including higher performance composites and some specified polymers. Even though these composite materials are characterised with better capability of damping such vibrations, their manufacturing costs are normally higher than the conventional damping materials such as rubber or foam. The complexity in the production of these advanced materials together with the high costs of the raw materials they are made from may be a nuisance particularly to small business and industries that are operates under small budgets. There is a potential for growth in overall costs which while not a certainty may hinder increased usage of more sophisticated damping solutions in particular applications where costs are more of an issue, such as in civil engineering or lower priced car markets.

However, the high production cost may cause high prices for the end consumer which may slow down the expansion of the market in regions with a sensitive pricing policy. In the sectors of consumer electronics and small appliances, reduction of the cost of production is critical, and this may lead to a reduction in the use of more elaborate materials for vibration damping solutions. For this reason, these materials are somehow costly and their high prices act as a brake to the growth of the market, especially in developing nations where cost plays a crucial role in determination of the materials to be used.

Vibration Damping Material Market Segment Analysis

Vibration Damping Material Market Segmented on the basis of material type, application and end user.

By Material Type

o Rubber

o Polyurethane

o Cork

o Foam

o Composites

o Others

By Application

o Noise Control

o Vibration Control

o Shock Absorption

By Region

o North America (U.S., Canada, Mexico)

o Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe)

o Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe)

o Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New-Zealand, Rest of APAC)

o Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa)

o South America (Brazil, Argentina, Rest of SA)

By Material Type, Rubber segment is expected to dominate the market during the forecast period

With regard to their composition, there are a number of forms of vibration damping material in use today and each form has its own appropriate uses depending on the situation. Rubber is one of the most popular materials for damping because of its high flexibility, ability of isolating vibrations and reasonable price. It is popular in automotive industry mainly as a part to reduce vibrations and sound in car engine mountings and suspensions. Polyurethane is also widely used as a material owing to its high ability of the reputed resilience and constant damping characteristics across variation in temperature and pressure. Due to its reinforcement capabilities, it is applied widely for high usage such as in industrial plants and construction plant.

Rubber, cork, foam, composites, and other such materials also happen to serve major functions in damping vibration. Cork provides good natural damping characteristics and is suitable for uni or bi-directional applications as well as for environmentally sound products. Foam, for example, is relatively light with high degree of application flexibility, a primary use being in the manufacture of consumer electronics and the automotive industry. Damped composites from fabric materials and plastic resins provide high performance damping used in aerospace and automotive products that contain lowered mass and durability. Every type of material is chosen when there is a need for a certain type of application, and over time new material types may be developed with improved characteristics.

By Application, Noise Control segment expected to held the largest share

The following are the common use of vibration damping materials; acoustic management, vibration management and shock management. Acoustic management is the act of minimizing sound generated by mechanical systems and other engines and equipment. Vibration control is primarily used to reduce the amplitude of mechanical vibrations which may cause equipment failure or discomfort. Energy dissipation materials and elements are created to prevent equipment or buildings from damage resulting from vibrations. For instance, damping engineering is employed in the manufacturing processes of vehicles, the engine, suspension and interior where it helps manufacturers to reduce noise hitches and generate better comfortable cars.

Another use of vibration damping materials is felt in segments like aerospace since the vibration emanating from engines and airframes of airplanes is well absorbed reducing the noise level and hence improving comfort of passengers as well as protection of delicate instruments. In construction, damping material is used to minimize the vibrations emanating from equipment including walking by people. Likewise in consumer electronics, the material for vibration damping helps to protect parts from vibrations that can easily destroy them and guarantee the lifespan of the products. For each of the applications, there will be more likely to be future requirements for differentiated damping materials that can be geared towards serving specific industries.

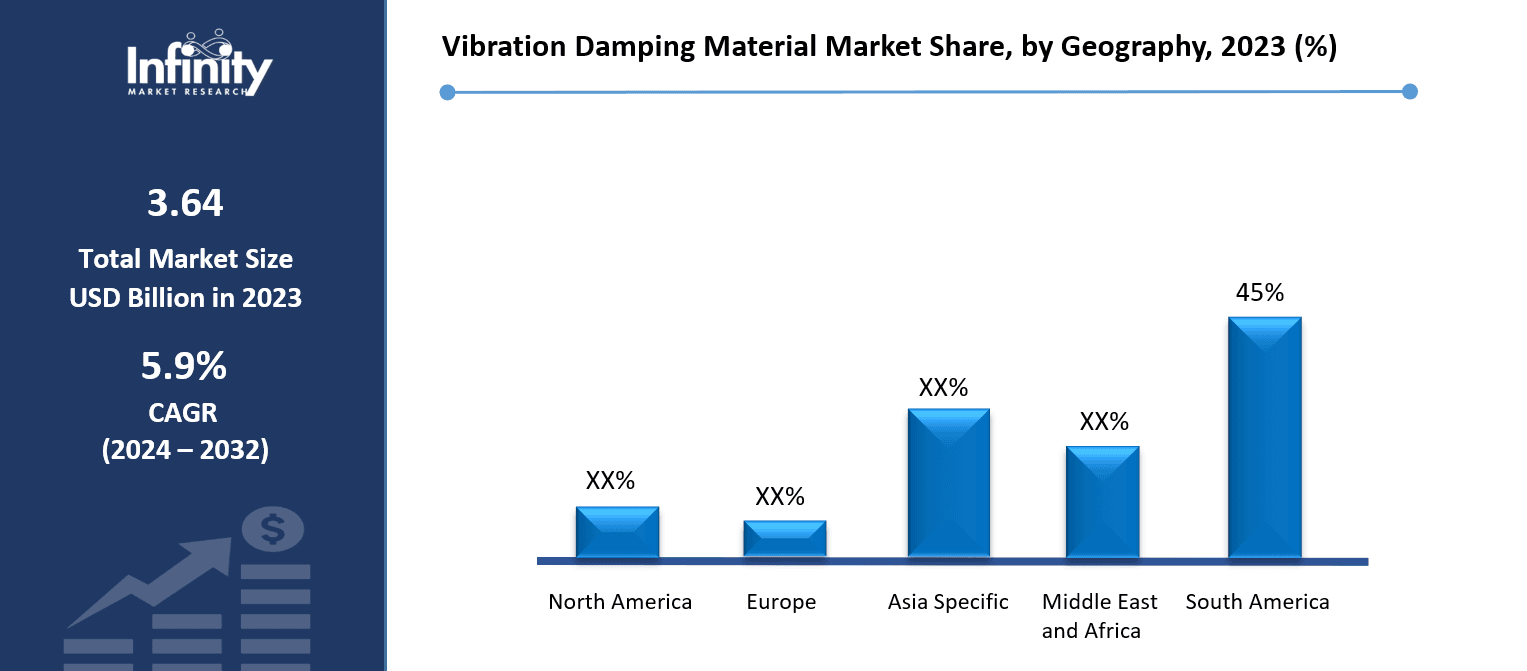

Vibration Damping Material Market Regional Insights

North America is Expected to Dominate the Market Over the Forecast period

North America has the largest market share at present in the Vibration Damping Material Market since it has well developed industrial segment and requirement of noise and vibration control. The automotive industry specifically in North America and more to the United States has greatly enhanced the product growth since the manufacturers persistently put emphasis to enhance the vehicle comfort and performance by incorporating vibration damping materials. Aerospace also forms another segment to the market mainly due to the need to develop materials that help in negating vibrations in civil and military aircrafts.

Also, North America has invested and featured strong in research and development activities necessary in the design of high performance damping materials. Another point is that the awareness of sustainability and environmentally friendly materials is also in accord with the common trends for green products and solutions in vibration damping. The favourable growth factors including a favourable market structure, well-developed market infrastructure, existence of important market players and the constant advancements in technology make North America region to remain the largest market for the vibration damping material market during the near future.

Vibration Damping Material Market Share, by Geography, 2023 (%)

Active Key Players in the Vibration Damping Material Market

o 3M (USA)

o BASF (Germany)

o Henkel AG & Co. (Germany)

o Trelleborg AB (Sweden)

o Soundcoat (USA)

o Saint-Gobain (France)

o Bridgestone Corporation (Japan)

o Huntsman Corporation (USA)

o Rogers Corporation (USA)

o DuPont (USA)

o Sika AG (Switzerland)

o LORD Corporation (USA)

o Other key Players

Global Vibration Damping Material Market Scope

|

Global Vibration Damping Material Market | |||

|

Base Year: |

2023 |

Forecast Period: |

2024-2032 |

|

Historical Data: |

2017 to 2023 |

Market Size in 2023: |

USD 3.64 Billion |

|

Forecast Period 2024-32 CAGR: |

5.9% |

Market Size in 2032: |

USD 6.10 Billion |

|

Segments Covered: |

By Material Type |

· Rubber · Polyurethane · Cork · Foam · Composites · Others | |

|

By Application |

· Noise Control · Vibration Control · Shock Absorption | ||

|

By Region |

· North America (U.S., Canada, Mexico) · Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe) · Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe) · Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New-Zealand, Rest of APAC) · Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa) · South America (Brazil, Argentina, Rest of SA) | ||

|

Key Market Drivers: |

· Technological Advancements in Material Science | ||

|

Key Market Restraints: |

· High Cost of Advanced Materials | ||

|

Key Opportunities: |

· Growing Demand for Electric Vehicles (EVs) | ||

|

Companies Covered in the report: |

· 3M (USA), BASF (Germany), Henkel AG & Co. (Germany), Trelleborg AB (Sweden), Soundcoat (USA), Saint-Gobain (France),Bridgestone Corporation (Japan), Huntsman Corporation (USA), and Other Major Players. | ||

📘 Frequently Asked Questions

1. What would be the forecast period in the Vibration Damping Material Market research report?

Answer: The forecast period in the Vibration Damping Material Market research report is 2024-2032.

2. Who are the key players in the Vibration Damping Material Market?

Answer: 3M (USA), BASF (Germany), Henkel AG & Co. (Germany), Trelleborg AB (Sweden), Soundcoat (USA), Saint-Gobain (France),Bridgestone Corporation (Japan), Huntsman Corporation (USA), and Other Major Players.

3. What are the segments of the Vibration Damping Material Market?

Answer: The Vibration Damping Material Market is segmented into Material Type, Application, End User and region. By Material Type, the market is categorized into Rubber, Polyurethane, Cork, Foam, Composites, Others. By End-Use Industry, the market is categorized into Automotive, Aerospace & Defense, Industrial Equipment, Consumer Electronics, Construction, Marine, Others. By Application, the market is categorized into Noise Control, Vibration Control, Shock Absorption. By region, it is analyzed across North America (U.S.; Canada; Mexico), Eastern Europe (Bulgaria; The Czech Republic; Hungary; Poland; Romania; Rest of Eastern Europe), Western Europe (Germany; UK; France; Netherlands; Italy; Russia; Spain; Rest of Western Europe), Asia-Pacific (China; India; Japan; Southeast Asia, etc.), South America (Brazil; Argentina, etc.), Middle East & Africa (Saudi Arabia; South Africa, etc.).

4. What is the Vibration Damping Material Market?

Answer: The Vibration Damping Material Market will mean the trade which is engaged in manufacturing or supplying the products that are especially produced to lessen the degrees of vibration as well as the noise produced by mechanical equipment, systems or structures. These materials are employed in automobile, aerospace, construction and manufacturing sectors for enhancing comfort, efficiency, and durability by reducing, isolating or damped vibrations and sound energy. Examples of Other Vibration Damping Products that are used are polymers, elastomers, composites & various other specialty products as per specific application requirements, have ability to reduce vibration & hence protect equipments and also have feature to minimize noise.

5. How big is the Vibration Damping Material Market?

Answer: Vibration Damping Material Market Size Was Valued at USD 3.64 Billion in 2023, and is Projected to Reach USD 6.10 Billion by 2032, Growing at a CAGR of 5.9% From 2024-2032.

🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

- Accurate & Verified Data:Our insights are trusted by global brands and Fortune 500 companies.

- Complete Transparency:No hidden fees, locked content, or misleading claims — ever.

- 24/7 Analyst Support:Our expert team is always available to help you make smarter decisions.

- Instant Savings:Enjoy a flat $1000 OFF on every report.

- Fast & Reliable Delivery:Get your report delivered within 5 working days, guaranteed.

- Tailored Insights:Customized research that fits your industry and specific goals.