🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

At Infinity Market Research, we dont just deliver data — we deliver clarity, confidence, and competitive edge.

In a world driven by insights, we help businesses unlock the infinite potential of informed decisions.

Here why global brands, startups, and decision-makers choose us:

Industry-Centric Expertise

With deep domain knowledge across sectors — from healthcare and technology to manufacturing and consumer goods — our team delivers insights that matter.

Custom Research, Not Cookie-Cutter Reports

Every business is unique, and so are its challenges. Thats why we tailor our research to your specific goals, offering solutions that are actionable, relevant, and reliable.

Data You Can Trust

Our research methodology is rigorous, transparent, and validated at every step. We believe in delivering not just numbers, but numbers that drive real impact.

Client-Centric Approach

Your success is our priority. From first contact to final delivery, our team is responsive, collaborative, and committed to your goals — because you re more than a client; you re a partner.

Recent Reports

Obesity Management Market

GLP-1 Receptor Agonist Market

Zinc Waste Recycling and Reusing Market

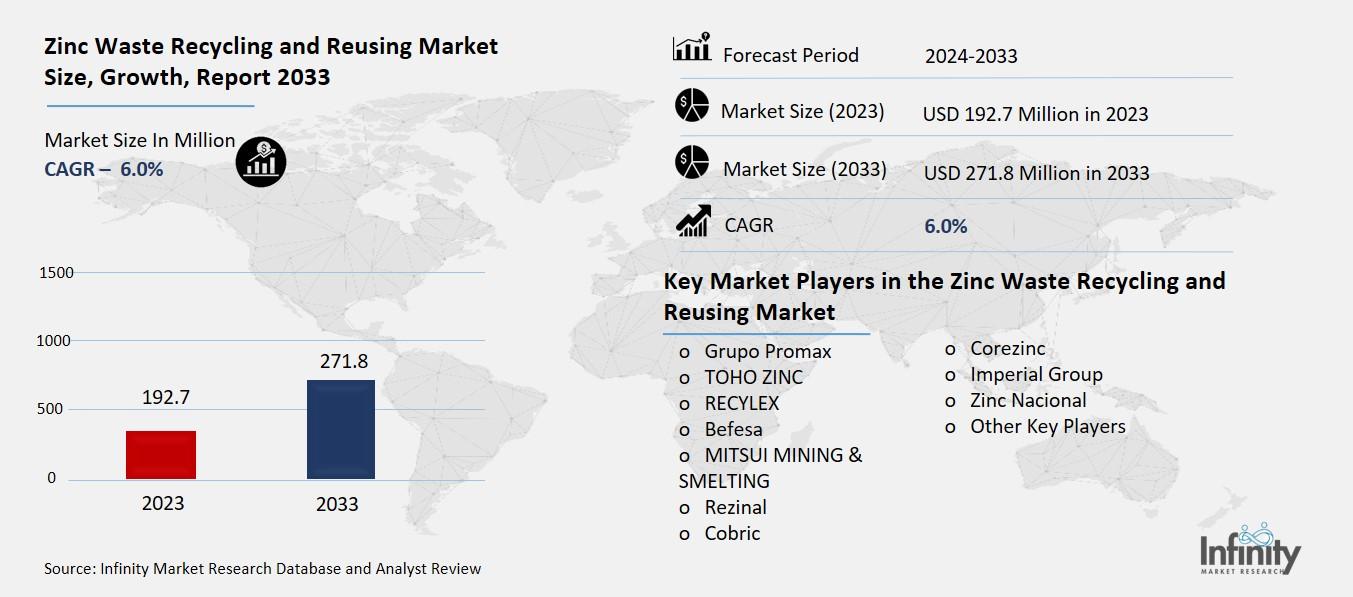

Global Zinc Waste Recycling and Reusing Market (By Type, Recycle and Reuse; By Application, Cosmetics, Medicines, Batteries, Paint, Rubber, and Other Applications; By Region and Companies), 2024-2033

Nov 2024

Chemicals and Materials

Pages: 138

ID: IMR1331

Zinc Waste Recycling and Reusing Market Overview

Global Zinc Waste Recycling and Reusing Market acquired the significant revenue of 192.7 Million in 2023 and expected to be worth around USD 271.8 Million by 2033 with the CAGR of 3.5% during the forecast period of 2024 to 2033. A rising segment of the waste management and recycling market is the recycling and reusing of waste zinc, stimulated by the society’s environmental protectiveness. High quantity of zinc, which is a material employed in different sectors including automotive, construction, and electronics industries, gets disposed as off-scrap, off-dust as well as off-residues.

Recovering and remanufacturing zinc waste has multiple advantages over direct zinc extraction, as the natural recovery of zinc is an energy-consuming and detrimental process. The market of zinc recycling is complex, and it encompasses the smelting method, distillation method, and the hydrometallurgical method in its operations to reclaim zinc from waste products. Some of the drivers that have an impact on this market include; Increased granularity of the costs of raw material, innovations in recycling infrastructure, and increased government influence towards recycling.

Drivers for the Zinc Waste Recycling and Reusing Market

Rising Demand for Sustainable Practices

Environmental consciousness has been realized to be one of the significant factors behind enhancement of better waste management and recycling. With the increase in the population of the people all over the world, and the increasing industrialization, there has been the need for more metal products among which is zinc. However, virgin zinc zinc that is mined directly from the ground is produced through highly mechanized and energy consuming processes that in themselves can lead to environmental degradation in form of deforestation, destruction of wildlife habitats and pollution. Second, the mining process leads to pollution and liberation of excessive carbon in the atmosphere leading to climate change.

Due to such environmental constraints, more emphasis is being placed on recycling and extending the usage of metals such as zinc reducing the amount of the metal that needs to be extracted from fresh sources. Recycling also works as a way to save useful materials and greatly reduces power use and emissions of dangerous gases taking into account the regular mining techniques.

Restraints for the Zinc Waste Recycling and Reusing Market

High Initial Investment in Recycling Infrastructure

The development of advanced recycling technologies and infrastructure, while essential for improving the efficiency and scalability of zinc recycling, often requires substantial capital investment. This financial burden can be a significant barrier, particularly in developing regions where resources for such large scale projects may be limited. Establishing state-of-the-art recycling facilities involves high upfront costs for machinery, research and development, and operational setup. Additionally, these advanced technologies, such as automated sorting systems, hydrometallurgical methods, and high-efficiency smelting processes, require ongoing investments in maintenance, workforce training, and technology upgrades to stay competitive.

Opportunity in the Zinc Waste Recycling and Reusing Market

Technological Advancements in Recycling Methods

The development of more efficient and cost-effective recycling technologies holds immense potential to drive market growth in the zinc recycling industry. As technological advancements improve the methods used to recover zinc from waste materials, the efficiency and effectiveness of the recycling process can significantly increase. This would lead to higher recovery rates, meaning more zinc can be extracted from waste with less material lost, reducing the overall need for virgin zinc mining. Additionally, innovations in recycling technologies can also improve the quality of the recycled zinc, ensuring that it meets the stringent requirements of various industries such as automotive, construction, and electronics.

Cost-effective recycling technologies not only make the process more affordable but also make it accessible to a wider range of industries and regions. For example, if the costs associated with setting up and running recycling facilities decrease, more companies and developing regions can invest in these technologies, resulting in greater global participation in zinc recycling.

Trends for the Zinc Waste Recycling and Reusing Market

Integration of Automation and AI in Recycling

The integration of automation and artificial intelligence (AI) in the zinc recycling process is transforming the industry by significantly improving recovery efficiency and reducing operational costs. Automation systems, such as robotic sorting technologies, enable the rapid and precise identification and separation of zinc-containing materials from waste streams. These systems can work continuously without fatigue, increasing throughput and reducing human error. Automated processes also allow for better optimization of resource usage, minimizing waste and maximizing recovery rates.

Artificial intelligence plays a critical role by enhancing the decision-making process in recycling operations. AI algorithms can analyze large volumes of data in real-time to identify patterns and predict optimal recycling parameters, such as temperature or chemical treatments, for zinc extraction.

Segments Covered in the Report

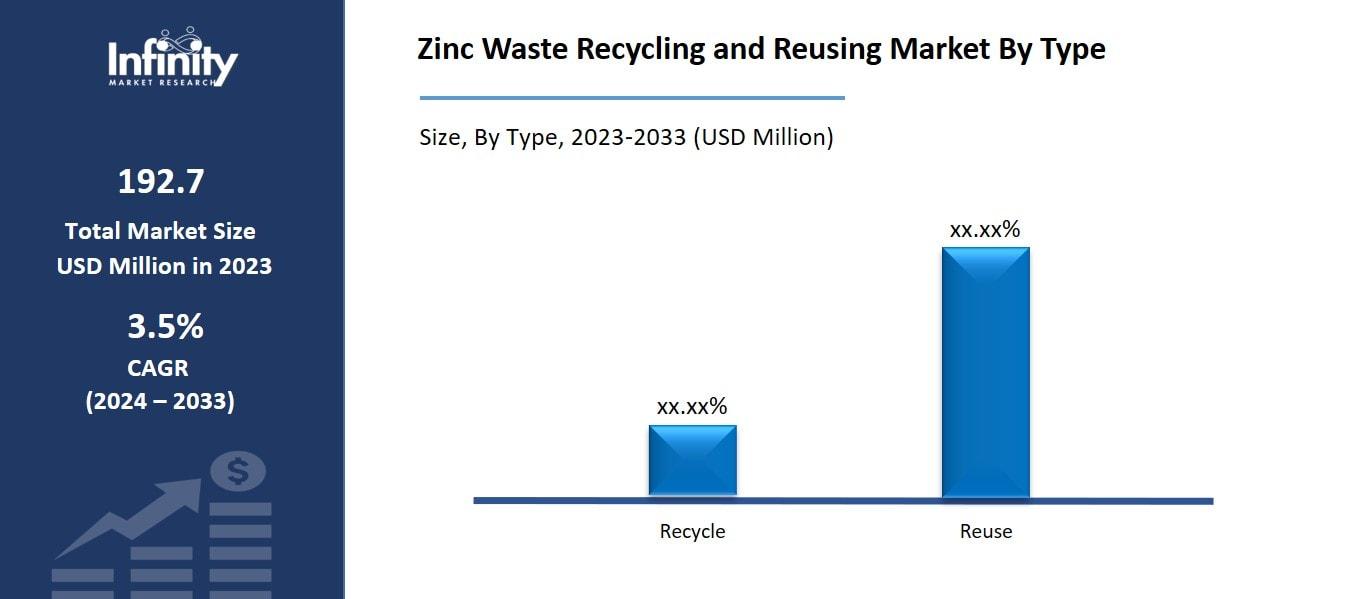

By Type

o Recycle

o Reuse

By Application

o Cosmetics

o Medicines

o Batteries

o Paint

o Rubber

o Other Applications

Segment Analysis

By Type Analysis

On the basis of type, the market is divided into recycle and reuse. Among these, recycle segment acquired the significant share in the market owing to the widespread adoption of recycling processes that extract zinc from various waste materials, such as industrial byproducts, electronic waste, and automotive scrap. Recycling methods, including pyro metallurgical and hydrometallurgical techniques, are extensively utilized to recover zinc, making the 'recycle' segment a major contributor to the market's growth.

By Application Analysis

On the basis of application, the market is divided into cosmetics, medicines, batteries, paint, rubber, and other applications. Among these, batteries segment held the prominent share of the market due to the growing demand for zinc in the production of zinc-based batteries, such as zinc-carbon and zinc-air batteries. Zinc is a critical component in these batteries, and with the rising need for energy storage solutions, especially in renewable energy and electric vehicles, the recycling of zinc from used batteries is gaining significant attention. This application benefits from both the high demand for zinc and the environmental focus on recycling materials to reduce waste and lower production costs.

Regional Analysis

North America Dominated the Market with the Highest Revenue Share

North America held the most of the share of 31.1% of the market. The region boasts a robust industrial base with high consumption of zinc, particularly in industries such as automotive, construction, and electronics, all of which generate substantial zinc waste. This large supply of zinc waste creates opportunities for recycling, contributing to the market's growth. Additionally, North America is home to stringent environmental regulations and policies that encourage sustainable practices, including metal recycling, to reduce the environmental impact of mining and manufacturing processes.

The region also benefits from advanced recycling infrastructure, with many companies adopting state-of-the-art recycling technologies to improve zinc recovery rates and quality. The increasing focus on the circular economy and resource conservation further supports market expansion. Furthermore, the growing demand for recycled materials, particularly in sectors like batteries and galvanizing, aligns with North America's drive for sustainability and energy efficiency.

Competitive Analysis

The competitive landscape of the Zinc Waste Recycling and Reusing Market is characterized by the presence of several key players vying for market share through advancements in recycling technologies, strategic partnerships, and geographical expansion. Leading companies in the market focus on improving the efficiency and cost-effectiveness of their recycling processes to maximize zinc recovery and meet the increasing demand for recycled zinc in various industries, such as automotive, construction, and electronics.

Recent Developments

In April 2024, Hindustan Zinc and VEXL Environ Projects Pvt. Ltd. have signed a Memorandum of Understanding (MoU) to set up a pilot plant aimed at pioneering sustainable solutions through the utilization of waste and the creation of wealth.

Key Market Players in the Zinc Waste Recycling and Reusing Market

o Grupo Promax

o TOHO ZINC

o RECYLEX

o Befesa

o MITSUI MINING & SMELTING

o Rezinal

o Cobric

o Corezinc

o Imperial Group

o Zinc Nacional

o Other Key Players

|

Report Features |

Description |

|

Market Size 2023 |

USD 192.7 Million |

|

Market Size 2033 |

USD 271.8 Million |

|

Compound Annual Growth Rate (CAGR) |

3.5% (2023-2033) |

|

Base Year |

2023 |

|

Market Forecast Period |

2024-2033 |

|

Historical Data |

2019-2022 |

|

Market Forecast Units |

Value (USD Million) |

|

Report Coverage |

Revenue Forecast, Market Competitive Landscape, Growth Factors, and Trends |

|

Segments Covered |

By Type, Application, and Region |

|

Geographies Covered |

North America, Europe, Asia Pacific, and the Rest of the World |

|

Countries Covered |

The U.S., Canada, Germany, France, U.K, Italy, Spain, China, Japan, India, Australia, South Korea, and Brazil |

|

Key Companies Profiled |

Grupo Promax, TOHO ZINC, RECYLEX, Befesa, MITSUI MINING & SMELTING, Rezinal, Cobric, Corezinc, Imperial Group, Zinc Nacional, and Other Key Players. |

|

Key Market Opportunities |

Technological Advancements in Recycling Methods |

|

Key Market Dynamics |

Rising Demand for Sustainable Practices |

📘 Frequently Asked Questions

1. Who are the key players in the Zinc Waste Recycling and Reusing Market?

Answer: Grupo Promax, TOHO ZINC, RECYLEX, Befesa, MITSUI MINING & SMELTING, Rezinal, Cobric, Corezinc, Imperial Group, Zinc Nacional, and Other Key Players.

2. How much is the Zinc Waste Recycling and Reusing Market in 2023?

Answer: The Zinc Waste Recycling and Reusing Market size was valued at USD 192.7 Million in 2023.

3. What would be the forecast period in the Zinc Waste Recycling and Reusing Market?

Answer: The forecast period in the Zinc Waste Recycling and Reusing Market report is 2024-2033.

4. What is the growth rate of the Zinc Waste Recycling and Reusing Market?

Answer: Zinc Waste Recycling and Reusing Market is growing at a CAGR of 3.5% during the forecast period, from 2024 to 2033.

🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

- Accurate & Verified Data:Our insights are trusted by global brands and Fortune 500 companies.

- Complete Transparency:No hidden fees, locked content, or misleading claims — ever.

- 24/7 Analyst Support:Our expert team is always available to help you make smarter decisions.

- Instant Savings:Enjoy a flat $1000 OFF on every report.

- Fast & Reliable Delivery:Get your report delivered within 5 working days, guaranteed.

- Tailored Insights:Customized research that fits your industry and specific goals.