🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

At Infinity Market Research, we dont just deliver data — we deliver clarity, confidence, and competitive edge.

In a world driven by insights, we help businesses unlock the infinite potential of informed decisions.

Here why global brands, startups, and decision-makers choose us:

Industry-Centric Expertise

With deep domain knowledge across sectors — from healthcare and technology to manufacturing and consumer goods — our team delivers insights that matter.

Custom Research, Not Cookie-Cutter Reports

Every business is unique, and so are its challenges. Thats why we tailor our research to your specific goals, offering solutions that are actionable, relevant, and reliable.

Data You Can Trust

Our research methodology is rigorous, transparent, and validated at every step. We believe in delivering not just numbers, but numbers that drive real impact.

Client-Centric Approach

Your success is our priority. From first contact to final delivery, our team is responsive, collaborative, and committed to your goals — because you re more than a client; you re a partner.

Recent Reports

Obesity Management Market

GLP-1 Receptor Agonist Market

Microfibrillated Cellulose (Mfc) Market

Microfibrillated Cellulose (Mfc) Market Global Industry Analysis and Forecast (2024-2032) By Type(Mechanical Processed MFC, Chemical Processed MFC, Biological Processed MFC),By Application(Paper and Packaging, Paints and Coatings, Personal Care and Cosmetics, Food and Beverages, Pharmaceuticals, Composites, Others),By End-Use Industry(Pulp and Paper, Food and Beverage, Pharmaceutical, Automotive, Construction, Others) and Region

Jan 2025

Chemicals and Materials

Pages: 138

ID: IMR1585

Microfibrillated Cellulose (Mfc) Market Synopsis

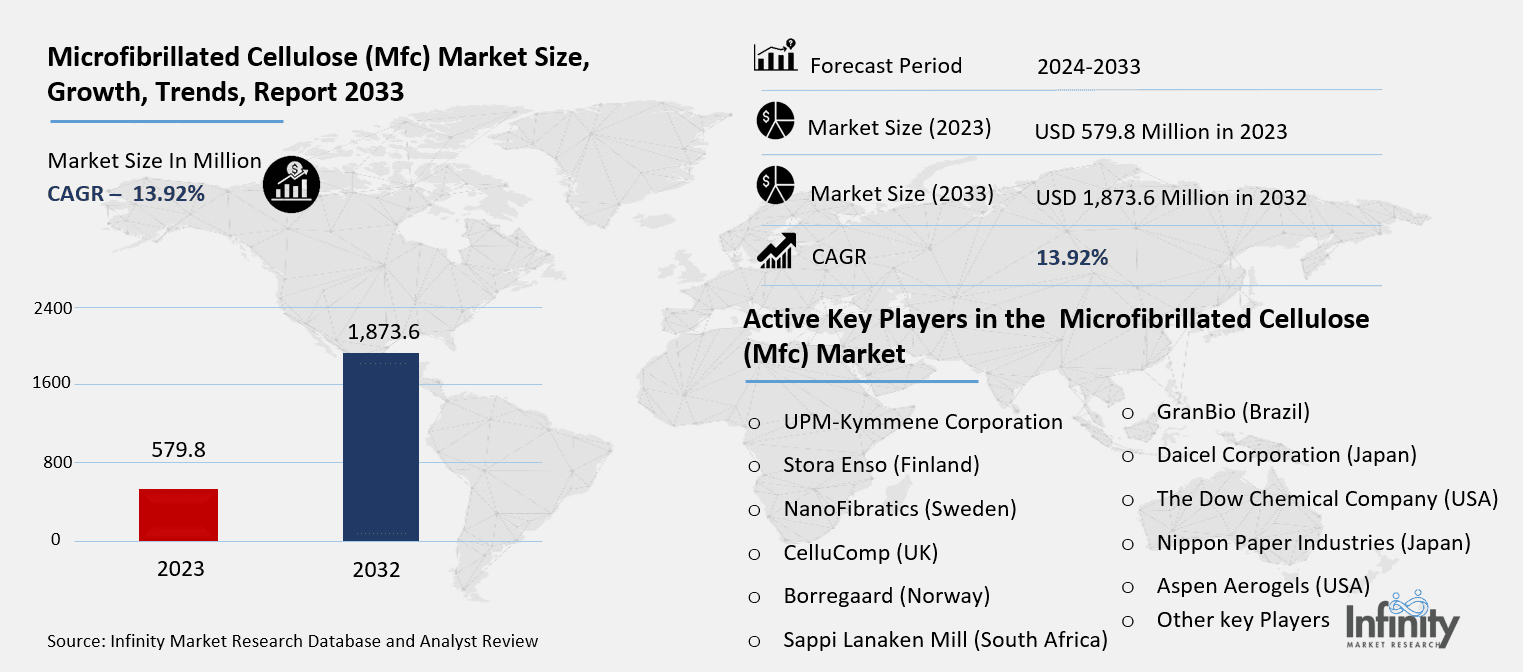

Microfibrillated Cellulose (Mfc) Market Size Was Valued at USD 579.8 Million in 2023, and is Projected to Reach USD 1,873.6 Million by 2032, Growing at a CAGR of 13.92% From 2024-2032.

Microfibrillated Cellulose (MFC) is a nanoscale cellulose material, that is renewable biopolymer which cellulosic source originates from plant fibres. This is due to high tensile strength, high surface area, and god capability of retaining water that enables the material to work effectively in many different industries. MFC is made from altering cellulose fibers to form smaller fibrils by mechanical, chemical, or biological methods to have gelly like structure normally used in paper and packaging, food, pharmaceutical and many other sectors.

Currently the Microfibrillated Cellulose (MFC) is just one of the segments of the bioplastics and renewable material market. MFC has relatively low environmental effects and is a replacement material for products that were usually made from conventional petrochemicals. This is because it is produced from renewable natural resources such as wood, cotton and hemp thus considered suitable for industries that seek to eliminate the use of raw materials which are in дан.DESCRIPTION limited supply. The enhancement in the use of eco-friendly and biodegradable polymers in diverse sectors including packaging, pharmaceuticals and food sectors is the major factor for the market growth.

MFC has attracted much attention recently because of the emphasis of industries toward sustainability and environmental protection. In the paper and packaging industry, MFC is used to increase paper quality by increasing paper’s strength and durability and decreasing the weight and amount of material used. In paints and coatings, where it has a role of rheological agent or thickeners, modifying the texture of the final products. Also, MFC is employed in the personal care products such as cosmetics for which high water retention and stabilizing capabilities are preferable. Food and beverage industry also uses MFC in specific products as a stabilizer or as an emulsifier while going in for its organic and safe attribute.

Another large scale application of MFC is in the pharmaceutical sector where it serves as binder for the formulation of tablets since MFC is both biocompatible and non-toxic. In the composites industry MFC is used in the form of reinforcement in light weight composites this is a sustainable commodities especially in the automobiles and construction industries. In summary it can be concluded that MFC market is growing because of the wide applicability of the material, versatility of the MFC and the tendency of the consumer and industrial market to shift toward renewable and eco-friendly materials instead of synthetics.

Microfibrillated Cellulose (Mfc) Market Outlook, 2023 and 2032: Future Outlook

Microfibrillated Cellulose (Mfc) Market Trend Analysis

Trend: Increasing Demand for Sustainable Packaging

These include packaging since the world’s focus has shifted towards protection of the environment and sustainability. Industry customers, including consumer listeners, are gradually waking up to the harm caused by plastics wastes to the environment, thus forcing manufacturers to look for environmentally-friendly materials such as MFC in packaging. Many features of MFC include increased strength and durability of such paper based goods while at the same time minimizing the material required; an option that works well for sustainable packaging.

To meet this need, many packaging companies are using MFC to form resulting in lightweight, biodegradable and recyclable packaging materials. Overall, the application in packaging helps decrease the consumption of plastics and convert packaging materials into ‘circular’ ones. It can be anticipated that the trend toward sustainable packaging will persist, which will require MFC for use in packaging.

Opportunity: Expansion in Emerging Markets

New opportunities for the development of the MFC market are associated with emerging regions for MFC, including Asia-Pacific, Latin America, Africa. With these regions continuing to go through a process of industrialization and urbanization, there are ever increasing calls for materials of sustainability throughout several product segments such as packaging, personal and food and processing. Rising consciousness about global environmental concerns and the demand for non-hazardous products are the primary drivers in the development of the MFC market in these locations.

Firms in the emerging markets are also awaking to the benefits of MFC as one of the cheapest and ecofriendly option for manufacturing firms. Based on present trends of increased production of packaged goods, pharmaceutical and food industries in these regions, MFC suppliers are best placed to explore new market frontiers by providing sustainable material. In this context, the importance of MFC for industrial development in these markets should increase as these markets grow.

Driver: Growing Demand for Eco-Friendly and Renewable Materials

Fluctuations of the global economy and concerns related to sustainability are important causes that define the MFC market including the increase in the usage of eco-friendly and renewable materials. As world governments and industries aim towards containing emissions and deploying more sustainable sources, MFC offers a credible substitute for synthetic polymers. As derived from natural, renewable plant fibers, the use of MFC addresses present market trends towards the utilization of biodegradable and toxic-free products in most industrial sectors.

Further, MFC has been amplified to embrace customer demand for products that have little or no impact on the environment. Consumers expect that they are going to be served with products that they know or have realized that the merchandise they are going to use are causing harm to the environment hence forcing those companies that want to survive out to look for environmentally friendly products. While industries try to cater to these needs, the MFC market is projected to grow due to the demands of sustainable environmentally friendly approaches in many applications.

Restraints: High Production Costs

The major problem affecting the MFC market is the high cost of production with regard to the manufacturing of the MFC. The manufacturing process of MFC is complex, involving high technological input hence the need for special equipment and that can be costly. Also, the basic components of MFC and other bio based composites, including wood fibers, must go through processes that demand energy and time to complete, and this adds to cost greatly.

These high production costs put MFC at a disadvantage with other traditional materials especially considering the price delicate industries. Although there is increasing demand for mitochondria free construction, the carrying cost of MFC may be more expensive to make it less favorable in some markets with stiff price competition. This cost barrier therefore becomes problematic for MFC manufacturers seeking to gain market share and saturated markets burdened with options that are cheaper than those listed here.

Microfibrillated Cellulose (Mfc) Market Segment Analysis:

Microfibrillated Cellulose (Mfc) Market Segmented on the basis of type, application and end user.

By Type

o Mechanical Processed MFC

o Chemical Processed MFC

o Biological Processed MFC

By Application

o Paper and Packaging

o Paints and Coatings

o Personal Care and Cosmetics

o Food and Beverages

o Pharmaceuticals

o Composites

o Others

By Region

o North America (U.S., Canada, Mexico)

o Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe)

o Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe)

o Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New-Zealand, Rest of APAC)

o Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa)

o South America (Brazil, Argentina, Rest of SA)

By Type, Mechanical Processed MFC segment is expected to dominate the market during the forecast period

The Microfibrillated Cellulose (MFC) market is segmented based on the processing methods used to produce the material: mechanical, chemical and biological. All of these types have their own peculiar properties and are suitable for the usage in some certain situations. The mechanical processed MFC is made by using the high pressure grinding process for the cellulose fibers, and therefore used in paper, packaging, and coatings, where high strength is necessary.

Chemical processed MFC is obtained by chemically treating cellulose fibers which can improve some properties such as dispersive and specific surface areas. This type of MFC is mainly employed in high stakes application like the composites and pharmaceuticals. Biological processed MFC, that is, MFC prepared through enzymatic or microbial treatments, is more eco friendly and is expected to find use in those areas where use of MFC can result in significant environmental impacts specifically food and personal care products.

By Application, Paper and Packaging segment expected to held the largest share

Microfibrillated Cellulose (MFC) is used in paper and packaging, paints and coatings, personal care, food and beverage, pharmaceutical and composite industries. In paper and packaging industry the MFC is used to enhance tensile strength, durability and recyclability of paper based products. Recently, it is extended as other material to replace the plastic, this benefits the concept of green environmental protection packaging.

Within paints and coatings industry MFC is used as rheology modifier, which enhances texture /viscosity of the final product. Similarly, they attributed certain characteristics of the building block to a positive effect that MFC has on the personal care and cosmetic industry categorically due to its stability and water holding qualities hence relevant in creams, lotions and gels. The MFC serves as a stabilizer or emulsifier in the formulation of sauces, dressings and beverages in the F&B sector; It is also used in the pharmaceutical sector as a binder in tablet schemes.

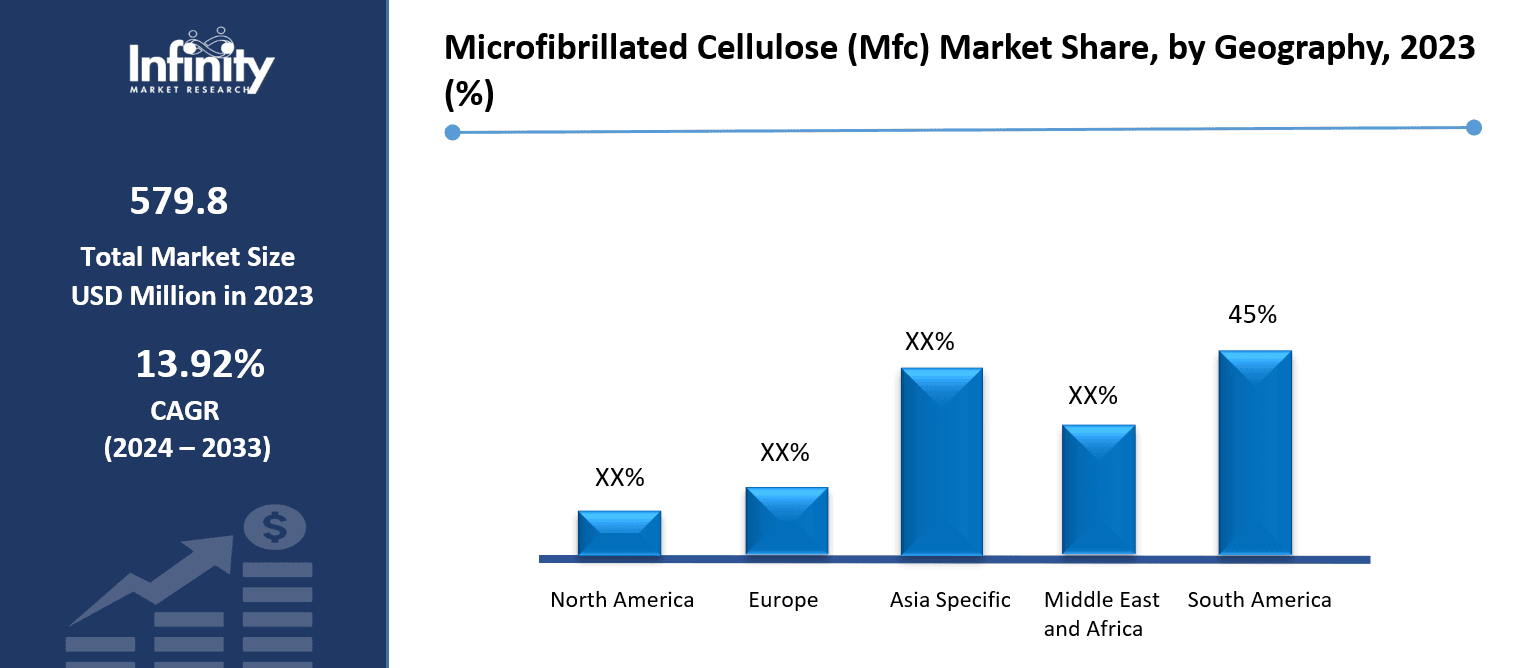

Microfibrillated Cellulose (Mfc) Market Regional Insights

North America is Expected to Dominate the Market Over the Forecast period

Due to the increasing emphasis on sustainability in the commercial market, North America shows a greater adoption towards Microfibrillated Cellulose (MFC) and is expected to dominate the global market in case of demand for it. The United States and Canada are the global pioneers of renewable materials with reference to the shift to environmentally friendly production processes. In addition, North America is dominant in the market because MFC’s key players are involved in research and production.

North America MFC market is expected to be driven by rising demand for sustainable product packaging materials and usage of renewable materials in paper and packaging, automotive and pharmaceutical industries. The policies used by the region to eliminate plastics and encourage biodegradable material use also help in the development of MFC markets. For these reasons, North America can sustain the current market leadership in the MFC market in the long run.

Microfibrillated Cellulose (Mfc) Market Share, by Geography, 2023 (%)

Active Key Players in the Microfibrillated Cellulose (Mfc) Market

o UPM-Kymmene Corporation (Finland)

o Stora Enso (Finland)

o NanoFibratics (Sweden)

o CelluComp (UK)

o Borregaard (Norway)

o Sappi Lanaken Mill (South Africa)

o GranBio (Brazil)

o Daicel Corporation (Japan)

o The Dow Chemical Company (USA)

o Nippon Paper Industries (Japan)

o Aspen Aerogels (USA)

o Glatfelter (USA)

o Other key Players

Global Microfibrillated Cellulose (Mfc) Market Scope

|

Global Microfibrillated Cellulose (Mfc) Market | |||

|

Base Year: |

2023 |

Forecast Period: |

2024-2032 |

|

Historical Data: |

2017 to 2023 |

Market Size in 2023: |

USD 579.8 Million |

|

Forecast Period 2024-32 CAGR: |

13.92% |

Market Size in 2032: |

USD 1,873.6 Million |

|

Segments Covered: |

By Type |

· Mechanical Processed MFC · Chemical Processed MFC · Biological Processed MFC | |

|

By Application |

· Paper and Packaging · Paints and Coatings · Personal Care and Cosmetics · Food and Beverages · Pharmaceuticals · Composites · Others | ||

|

By Region |

· North America (U.S., Canada, Mexico) · Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe) · Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe) · Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New-Zealand, Rest of APAC) · Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa) · South America (Brazil, Argentina, Rest of SA) | ||

|

Key Market Drivers: |

· Growing Demand for Eco-Friendly and Renewable Materials | ||

|

Key Market Restraints: |

· High Production Costs | ||

|

Key Opportunities: |

· Expansion in Emerging Markets | ||

|

Companies Covered in the report: |

· UPM-Kymmene Corporation (Finland), Stora Enso (Finland), NanoFibratics (Sweden), CelluComp (UK), Borregaard (Norway), Sappi Lanaken Mill (South Africa), GranBio (Brazil), and Other Major Players. | ||

📘 Frequently Asked Questions

1. What would be the forecast period in the Microfibrillated Cellulose (Mfc) Market research report?

Answer: The forecast period in the Microfibrillated Cellulose (Mfc) Market research report is 2024-2032.

2. Who are the key players in the Microfibrillated Cellulose (Mfc) Market?

Answer: UPM-Kymmene Corporation (Finland), Stora Enso (Finland), NanoFibratics (Sweden), CelluComp (UK), Borregaard (Norway), Sappi Lanaken Mill (South Africa), GranBio (Brazil), and Other Major Players.

3. What are the segments of the Microfibrillated Cellulose (Mfc) Market?

Answer: The Microfibrillated Cellulose (Mfc) Market is segmented into Type, Application, End User and region. By Type, the market is categorized into Mechanical Processed MFC, Chemical Processed MFC, Biological Processed MFC. By Application, the market is categorized into Paper and Packaging, Paints and Coatings, Personal Care and Cosmetics, Food and Beverages, Pharmaceuticals, Composites, Others. By End-Use Industry, the market is categorized into Pulp and Paper, Food and Beverage, Pharmaceutical, Automotive, Construction, Others. By region, it is analyzed across North America (U.S.; Canada; Mexico), Eastern Europe (Bulgaria; The Czech Republic; Hungary; Poland; Romania; Rest of Eastern Europe), Western Europe (Germany; UK; France; Netherlands; Italy; Russia; Spain; Rest of Western Europe), Asia-Pacific (China; India; Japan; Southeast Asia, etc.), South America (Brazil; Argentina, etc.), Middle East & Africa (Saudi Arabia; South Africa, etc.).

4. What is the Microfibrillated Cellulose (Mfc) Market?

Answer: Microfibrillated Cellulose (MFC) is a nanoscale cellulose material, that is renewable biopolymer which cellulosic source originates from plant fibres. This is due to high tensile strength, high surface area, and god capability of retaining water that enables the material to work effectively in many different industries. MFC is made from altering cellulose fibers to form smaller fibrils by mechanical, chemical, or biological methods to have gelly like structure normally used in paper and packaging, food, pharmaceutical and many other sectors

5. How big is the Microfibrillated Cellulose (Mfc) Market?

Answer: Microfibrillated Cellulose (Mfc) Market Size Was Valued at USD 579.8 Million in 2023, and is Projected to Reach USD 1,873.6 Million by 2032, Growing at a CAGR of 13.92% From 2024-2032.

🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

- Accurate & Verified Data:Our insights are trusted by global brands and Fortune 500 companies.

- Complete Transparency:No hidden fees, locked content, or misleading claims — ever.

- 24/7 Analyst Support:Our expert team is always available to help you make smarter decisions.

- Instant Savings:Enjoy a flat $1000 OFF on every report.

- Fast & Reliable Delivery:Get your report delivered within 5 working days, guaranteed.

- Tailored Insights:Customized research that fits your industry and specific goals.